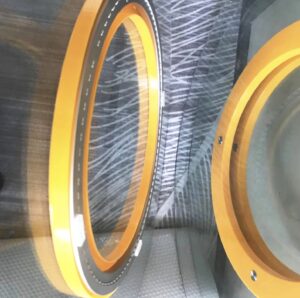

Lightweight aluminum alloy turntable bearings are entry-level cost-effective products. With more than 20 years of technological accumulation, they have become a classic choice for low-load-bearing scenes such as dining tables and light display stands.

Its core advantages include:

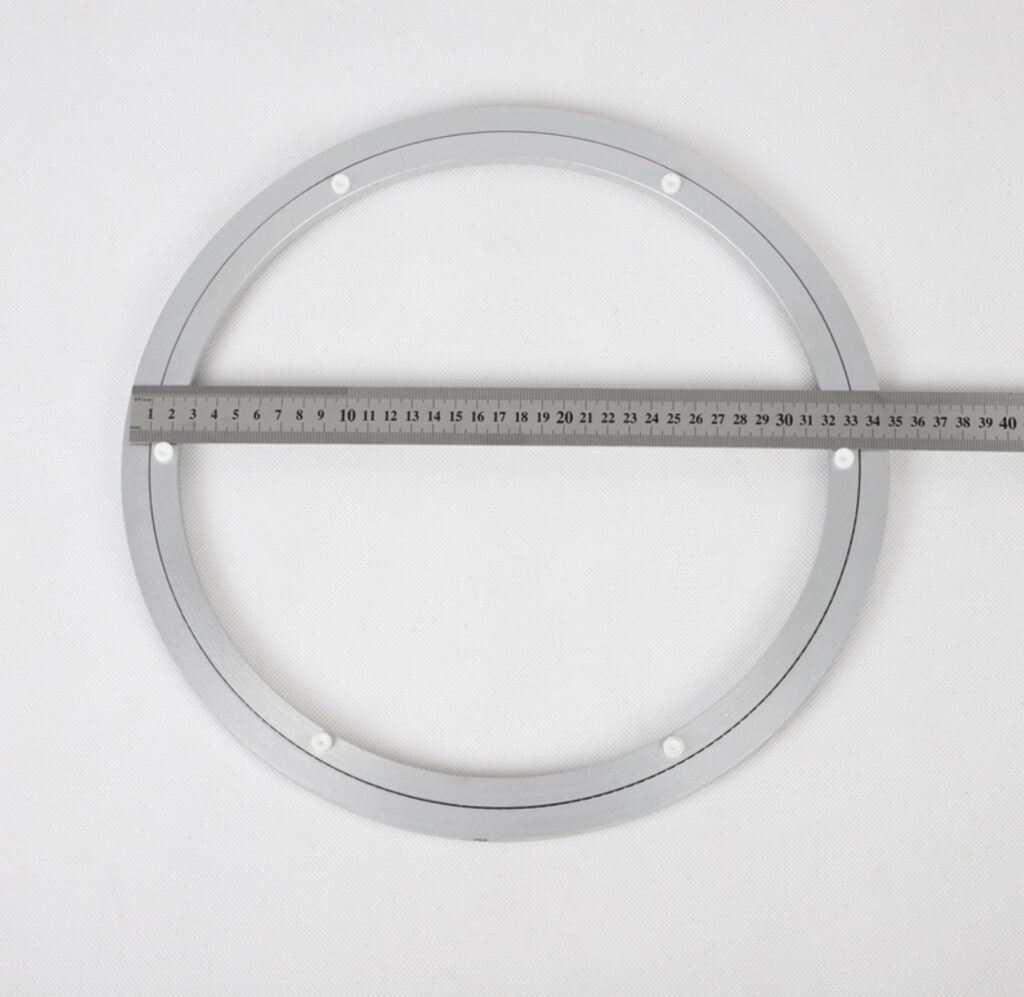

Lightweight design: Made of high-strength aluminum alloy, the 14-inch standard model with an outer diameter of 350mm, an inner diameter of 298mm, and a thickness of 10mm can safely bear a load of 60kg, far exceeding the standards of similar lightweight bearings.

Long life guarantee: Through factory actual measurement and verification, it supports more than 200,000 smooth rotations (calculated at 100,000 revolutions/year, with a lifespan of more than 20 years), and rejects short-term high-load false propaganda.

Full size coverage: The diameter ranges from 4 inches (106mm) to 32 inches (798mm), supports customized production, and adapts to the needs of different scenarios.

Precision Manufacturing: Relying on more than 30 years of aluminum product processing experience, the entire process from casting, CNC machining to surface treatment is automatically controlled, and the bearing hole position accuracy reaches the micron level, solving the installation deviation pain point of similar products on the market.

Application Scenario: Suitable for scenarios such as home furniture, light equipment turntables, commercial display racks, etc. that require a load-bearing capacity of ≤60kg. If a higher load is required, it is recommended to choose a reinforced or three-row roller structure product with the same diameter.

Technical Commitment: All parameters are tested under actual working conditions and provide lifelong technical support. If you need customization or technical consultation, please contact the UTOT professional team.